History

Rooted in tradition, and innovative to the core

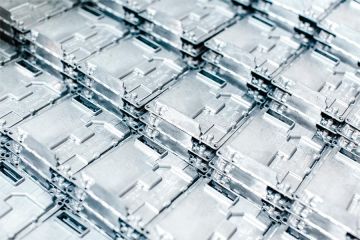

Rigorous quality focus, a value-driven approach to business and management, and far-sighted passion for innovation made our company what it is today: One of the most advanced and successful independent foundries in the whole of Germany.

The history of Druckguss Westfalen goes back to 1964. In that year, the two engineers Georg Weddige and Konrad Lehmkühler started the foundry with just four zinc die casting machines in Störmede, a district of Geseke in Westphalia. From the outset, the emphasis was on technical components made to the highest standards of quality. The business continuously expanded over the years. Customers from the office furniture industry were the main focus to begin with. Today, our family firm services a variety of industries, from automotive to electrical and medical engineering.

Druckguss Westfalen: Timeline

1964: Company foundation and commencement of zinc die casting production

1970: Acquisition of a die casting business in Dinslaken

1972: Changeover to aluminium die casting at Störmede location.

1985: Purchase of today’s premises, a 45,000 square metre site in Geseke. Machining relocated to the new site.

1990: Construction of a second, new foundry at the Geseke location

1998: Construction of new, enlarged machining building

2000: Expansion of the new foundry

2005: DIN ISO 9001 quality management certification

2011: Construction of separate cleaning and control sections for maximum standards of cleanliness

2012: Zinc die casting relocated to new site in Heiligenhaus

2012: ISO/TS 16949 certification to meet specific automotive industry requirements

2012: 750 square metre foundry extension

2012: Construction of 1600 square metre logistics building

2014: 50th anniversary of Druckguss Westfalen

2015: Machining expanded to 12 machining centres

2015: DIN ISO 50001 certification

2016: Extension of the zinc die casting production by acquisition of the foundry Behringer Druckguss GmbH & Co. KG