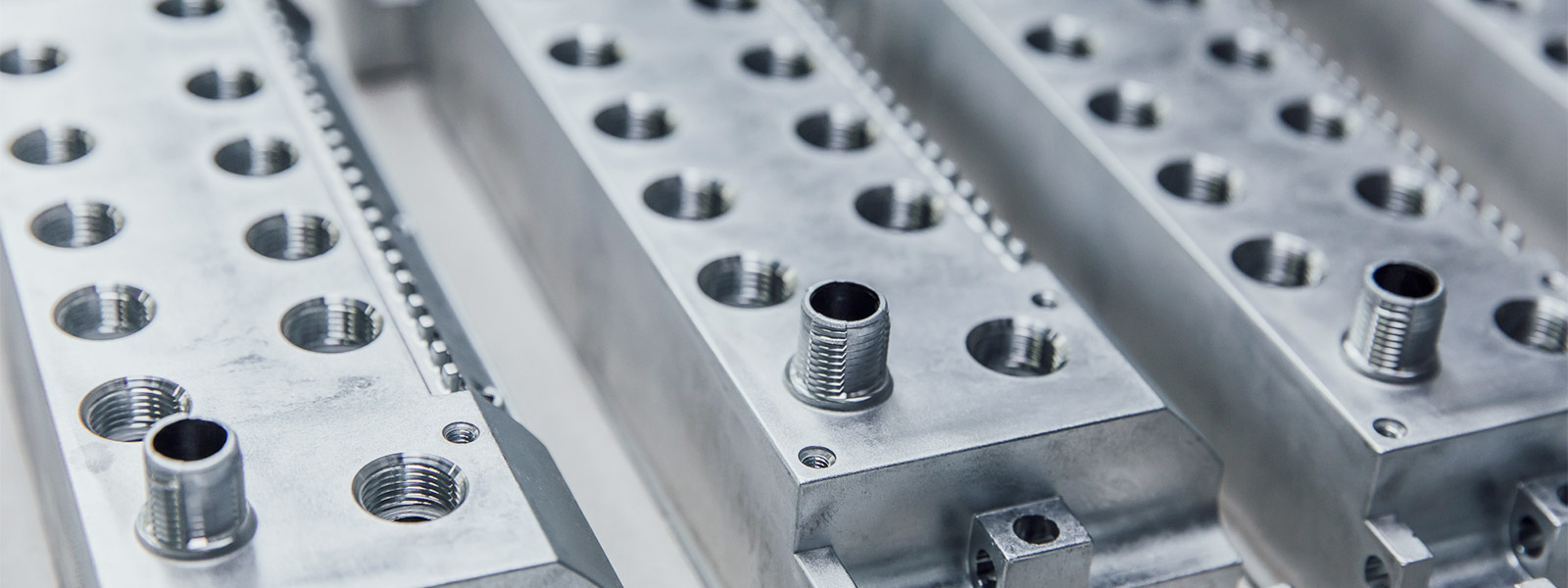

Zinc Die Casting

Complex geometries and quality finishing.

As zinc die casting specialists, our sister company Druckguss Westfalen Behringer has met the highest standards of precision and quality in medium to large production runs for over 40 years. In Velbert, 14 hot chamber die casting machines with clamping forces of 20 to 200 metric tons produce zinc die cast components with weights from around 0.5 g to 2000 g in accordance with a huge variety of different customer requirements.

Top-quality coating and plating for zinc die cast components

Using zinc it is possible to cast exceptionally intricate, thin-walled and technically demanding parts to very high precision. Subsequent machining is rarely necessary – provided that you work with specialists who, like Druckguss Westfalen Behringer, have vast experience in zinc die casting and apply the highest standards of quality. We additionally offer high-quality surface finishes with a very wide range of surface improvement options.

Chrome plating for long-lasting quality

Zinc die cast components are ideally suited for electroplating. Alongside standard coatings for corrosion-resistance, we also provide special finishes such as chrome plating or nickel plating. These achieve a truly premium look and feel.

Metal surface grinding and polishing

Professional surface treatment capabilities further add to the range of high-quality finishes for die cast components. We can provide decorative blasting and bright polished, matte and brushed surfaces – the ultimate in surface finishing. Finishing is performed by hand or robot, depending on batch size and complexity.